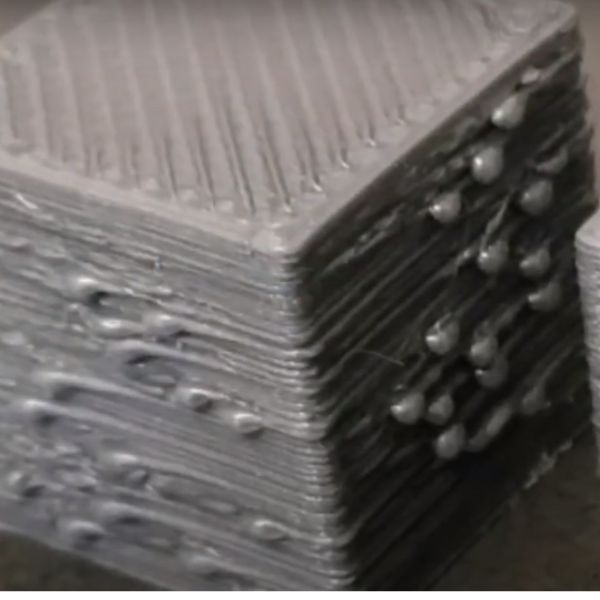

Over extrusion is a common problem in 3D printing where the printer pushes out too much filament. This can lead to prints that are messy, with blobs, strings, or rough surfaces. Understanding what causes over extrusion and how to fix it can help you produce cleaner and more precise 3D prints.

What is Over Extrusion?

Over extrusion happens when the 3D printer extrudes more filament than needed. This causes extra material to pile up on the print, creating uneven surfaces, blobs, or stringy sections. Over extruded prints can look messy and may not fit together properly if they are meant to connect with other parts.

Causes of Over Extrusion

Several factors can cause over extrusion:

- Incorrect Print Settings: If the extrusion multiplier or flow rate is set too high in the slicing software, the printer will push out more filament than necessary.

- Too High Printing Temperature: If the nozzle temperature is too high, the filament can become too liquid, causing more material to flow out than needed.

- Filament Diameter Mismatch: If the filament diameter set in the slicer software does not match the actual diameter of the filament being used, the printer might extrude too much material.

- Nozzle Issues: A damaged or oversized nozzle can lead to over-extrusion, as it allows more filament to flow out than intended.

How to Fix Over Extrusion?

To fix over extrusion, consider the following steps:

- Adjust Print Settings: Check the flow rate or extrusion multiplier settings in your slicing software like cura, slic3r, prusa slicer etc whatever you are using. Lower these settings slightly and test your print again to see if the problem improves.

- Lower the Printing Temperature: If the printing temperature is too high, reduce it slightly. This will make the filament less runny and help control the flow better.

- Check Filament Diameter: Measure the diameter of your filament with a caliper and ensure it matches the diameter setting in your slicer software. If there is a mismatch, update the setting to the correct value.

- Inspect the Nozzle: Make sure the nozzle is in good condition and of the correct size for your prints. If the nozzle is worn out or too large, replace it with a new one.

- Calibrate Your Printer: Regularly calibrate your 3D printer to ensure it is extruding the correct amount of filament. This includes checking the extruder steps per millimeter (steps/mm) settings.

Conclusion

Over extrusion can negatively impact the quality of your 3D prints, but it is usually easy to fix. By adjusting your print settings, checking the filament diameter, and keeping your printer well maintained, you can reduce over extrusion and achieve smoother, more precise prints. Properly managing over-extrusion will help you make the most out of your 3D printing projects.

I have written an extensive article about common defect in fdm 3d printing, you must read it –> common defects in fdm 3d printing

Defects in FDM 3D Printing