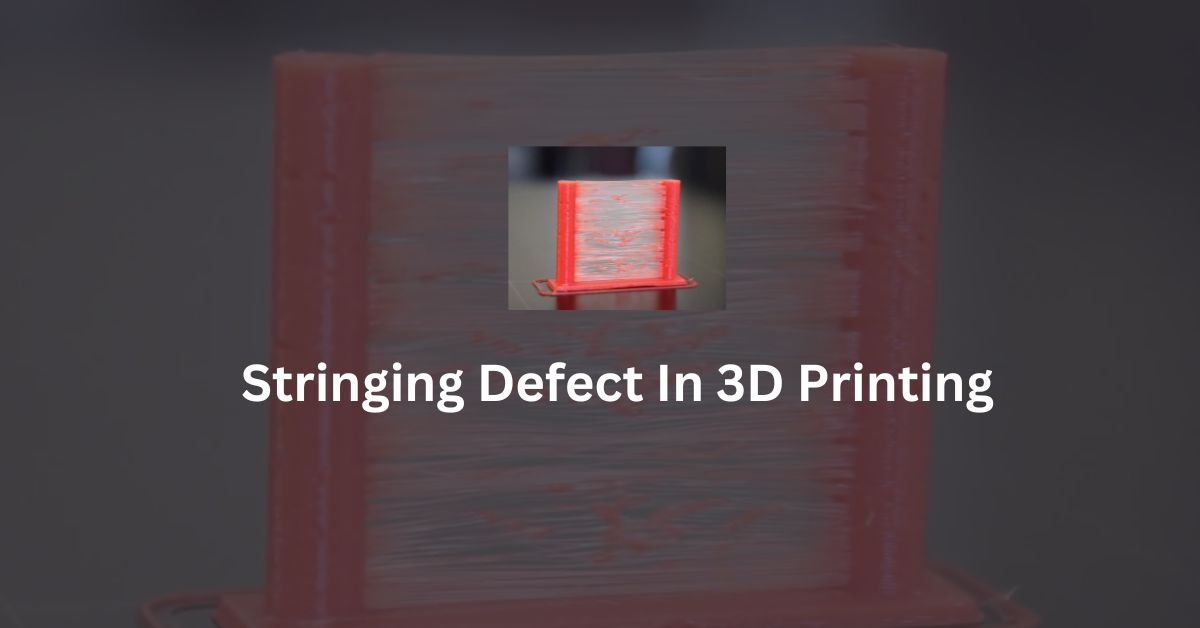

One common issue faced by many people using FDM (Fused Deposition Modeling) 3D printers is “stringing.” Stringing is when small, thin strands of filament appear on the surface of a 3D-printed object, making it look messy.

In this blog post, we’ll explore what causes stringing and how you can fix it.

What is Stringing?

Stringing happens when your 3d printer leaves thin threads of plastic between parts of your print. These strands are unwanted and can make your final product look unclean or unprofessional. Imagine a spider web connecting different parts of your 3d print – this is similar to stringing.

Why Does Stringing Happen?

Stringing occurs for a few reasons:

- High Temperature: When the nozzle temperature is too high, the filament becomes too liquid and can drip or ooze out when the nozzle moves from one place to another.

- Retraction Settings: Retraction is a feature in 3d printing where the filament is pulled back slightly into the nozzle to prevent it from oozing. If your retraction settings are not correct, stringing can occur.

- Filament Quality: Low-quality filament might not melt properly, leading to more stringing.

- Speed of Travel: If the printer moves too slowly between two points, there is more time for the filament to drip out of the nozzle, causing stringing.

How to Fix Stringing?

Luckily, stringing can be reduced or even eliminated by adjusting a few settings:

- Lower the Nozzle Temperature: Start by lowering your nozzle temperature by 5-10°C. This can help the filament stay firm when the nozzle moves.

- Adjust Retraction Settings: a) Increase Retraction Distance – Increase how much filament is pulled back into the nozzle. A higher retraction distance can prevent oozing. b) Increase Retraction Speed – Increase the speed at which the filament is pulled back or retracted. This can also help prevent the filament from dripping.

- Use Higher Travel Speed: Increase the speed at which the nozzle moves when it’s not printing. This reduces the time the nozzle has to ooze filament.

- Test Different Filaments: Not all filaments are created equal. If you notice stringing with one type of filament, try switching to a higher-quality filament.

- Keep Your Printer Clean: Sometimes, leftover filament in the nozzle can cause stringing. Regularly clean your nozzle to avoid this problem.

Conclusion

Stringing can be a frustrating issue in FDM 3D printing, but it is usually easy to fix. By adjusting your printer’s temperature, retraction settings, and travel speed, you can reduce or even eliminate stringing. Remember to test with different filaments and keep your printer well-maintained to get the best results.

With these tips, your 3D prints should come out clean and professional, free of those pesky strings! Happy printing!

Defects in FDM 3D Printing

Checkout this 8Tth pay commission salary calculator – 8th pay commission calculator