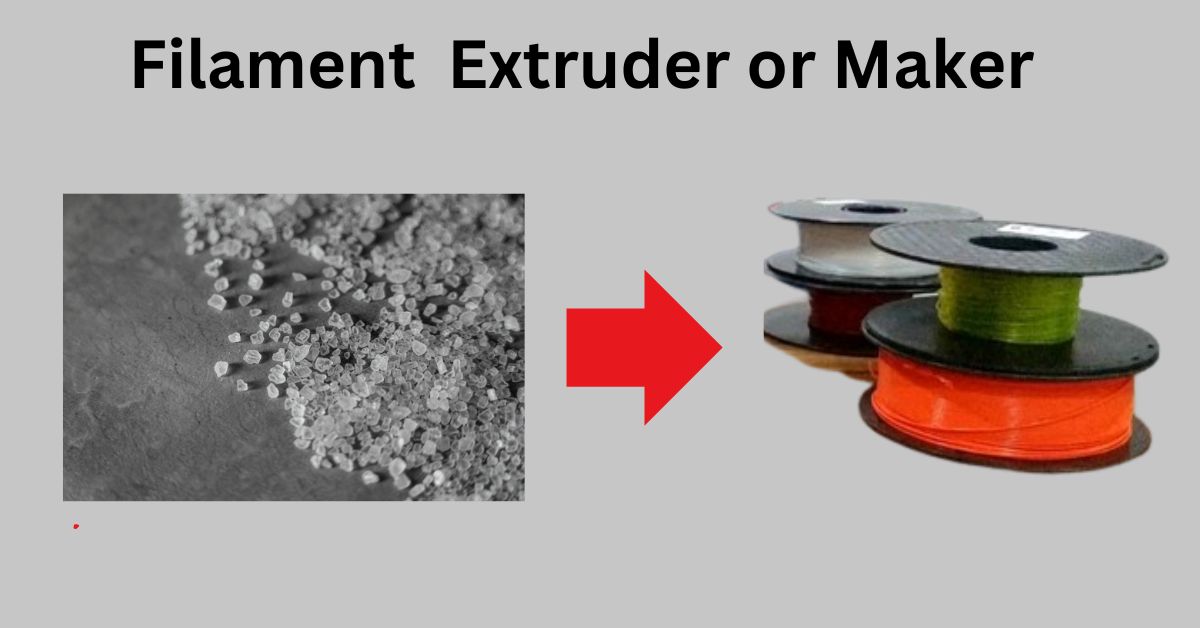

A 3D printer filament extruder or maker is a machine used to create the plastic filament that 3d printers use to build objects. Filament is like the “ink” for 3d printers, and an extruder makes it from raw plastic material. Let’s break down how it works, why it’s useful, and what you need to know about it.

How Does a Filament Extruder Work?

- Loading the Raw Material:

The process starts with raw plastic pellets, which are small granules of plastic. These pellets are often made from common materials like PLA (polylactic acid) or ABS (acrylonitrile butadiene styrene). - Melting the Plastic:

The pellets are fed into a heating chamber inside the extruder. This chamber heats up, melting the plastic into a thick, gooey liquid. - Pushing the Melted Plastic:

A screw or similar mechanism inside the extruder pushes the melted plastic through a small opening called a die. The size of hole in this die determines the thickness of the filament. - Cooling the Filament:

As the plastic comes out of the die, it’s still hot and soft. To solidify it into the filament, the extruder cools it down quickly, often using fans or water. - Winding the Filament:

Finally, the cooled filament is wound onto a spool, ready to be used in a 3D printer.

Why Use a Filament Extruder?

- Cost-Effective:

Buying raw plastic pellets and making your own filament is often cheaper than buying pre-made filament spools. This is especially useful for people who do a lot of 3D printing. - Custom Filament:

With a filament extruder, you can experiment with different materials and colors, creating custom filament that suits your specific needs. - Recycling:

Some extruders allow you to recycle old 3D prints or plastic waste by grinding it down and turning it back into new filament. This is great for reducing waste and saving money.

Things to Consider

- Initial Cost:

While making your own filament can save money in the long run, the initial cost of a filament extruder can be high. It’s an investment, so it’s essential to consider the advantages and disadvantages. - Quality Control:

Homemade filament may not always be as consistent as factory-produced filament. You’ll need to experiment and adjust your extruder settings to get the best results. - Time and Effort:

Making filament isn’t a quick process. It requires time and attention, so it’s something to consider if you’re thinking about making your own.

Conclusion

A 3D printer filament extruder is a useful tool for anyone looking to save money, experiment with materials, or reduce waste in their 3D printing projects. While it requires some investment and effort, the ability to create your own custom filament can be rewarding for both hobbyists and professionals alike.

This simple guide should help you understand the basics of a filament extruder and why it might be a valuable addition to your 3D printing toolkit.

If you enjoyed reading this article, please let me know in comments.

Defects in FDM 3D Printing

3D Printers In Your City:

3D Printing Services In Your City (Prototyping Service):